Empower Your Factory with

Digital Twin + AI

Leverage Real-time data analytics, Industrial AI assistants and Digital Twin of your industrial process to generate real, tangible value

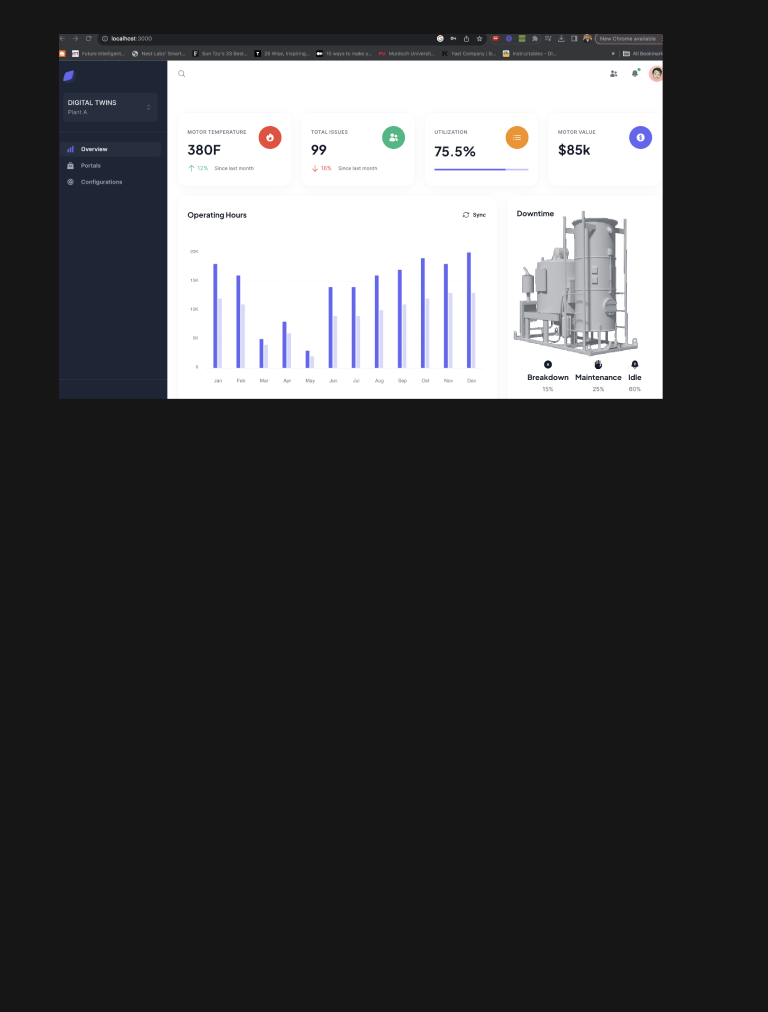

Asset Management

Use Digital twin to proactively keep track of equipment life-cycle and avoid costly breakdowns

Smart Monitoring

With real-time data and advanced insights , monitor the process health remotely or automatically

Predictive Analytics, AI

Unleash the real power of Data by plugging AI based operational recommendations into operations

ModernFactoryX

We help industrial enterprises solve some of the biggest challenges on the shop-floor and enhance their productivity and output.

15+

Projects Done

25+

Combined Years Exp

100%+

Return on Investment

How We Work For You?

ModernFactoryX builds state-of-the-art Digital Twins that are embedded with LLM – AI agents to immortalize, visualize and optimize your industrial processess.

Digital Library

Unify and contextualize your rich library of documentation, tribal knowledge and event history with the power of the twin.

Maintenance and management

Leverage real-time analytics, 3rd party software and AI agents for maintenance monitoring and management.

Recommendations and AI

Our AI agents can deliver insights and recommendations with the help of digital library , past events and operational best practices.

ModernFactoryX

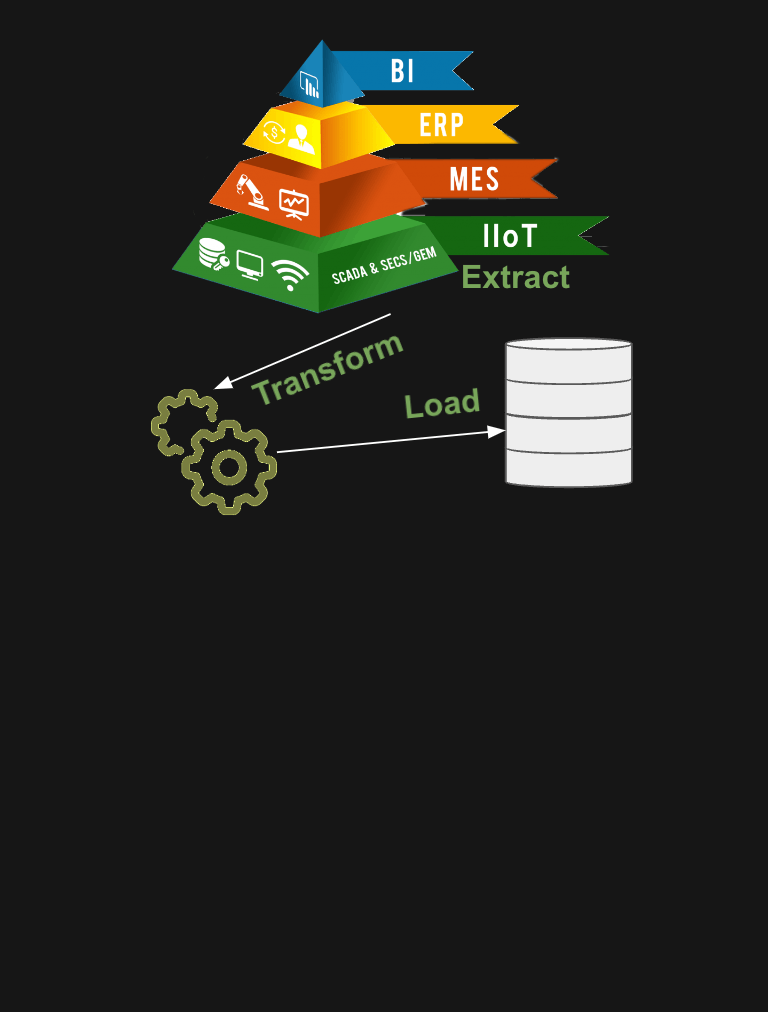

Technical Steps Involved in a typical digital twin building project

01. Data Engineering

Connect to various sources and build high-performance, scalable and secure data pipelines.

02. Digital Assets Modelling

Develop twin assets like 3D artifacts, ML models and physics engineering.

03. Value Creation

Apply Data Science to derive intelligence and generate business value.

Website is

Being updated

Newsletter, Case-Studies and more information coming soon !

Windsor, Canada

Windsor, Canada